Major retailers are increasingly focused on enhancing their use of sustainable packaging materials for meat products. While mono-material packs facilitate better recyclability, vacuum skin packs successfully reduce plastic volume without sacrificing shelf life.

Nevertheless, as this transition evolves, modified atmosphere packaging (MAP) remains a preferred choice for numerous products where extended shelf life and freshness are paramount. This preference is understandable—MAP technology provides a cost-effective solution, particularly for economical meats such as poultry, sausages, and minced varieties like beef, pork, lamb, and turkey. Additionally, MAP improves shelf presentation, catering to consumer familiarity with products displayed in trays featuring film lids.

It remains uncertain whether retailers will favor more skin-packed meats or continue their loyalty to MAP. However, one fact is clear: meat processors utilizing MAP must ensure their packs are effectively sealed to prevent premature spoilage. Any lapses in sealing can result in stock rejections by retailers, leading to significant financial and reputational risks.

Ensuring Seal Integrity in Meat Packaging

In light of this, decision-makers at meat processing plants must explore effective options to guarantee peace of mind regarding MAP. Seal integrity emerges as the most critical factor; however, it should not compromise productivity. Maintaining high throughput is essential to meet quotas, minimize product wastage, and keep production costs low.

Stakeholders in meat processing should therefore invest in reliable, high-quality tray sealer solutions. This strategic investment helps mitigate risks associated with rising costs, performance issues, operational efficiency, and sustainability challenges.

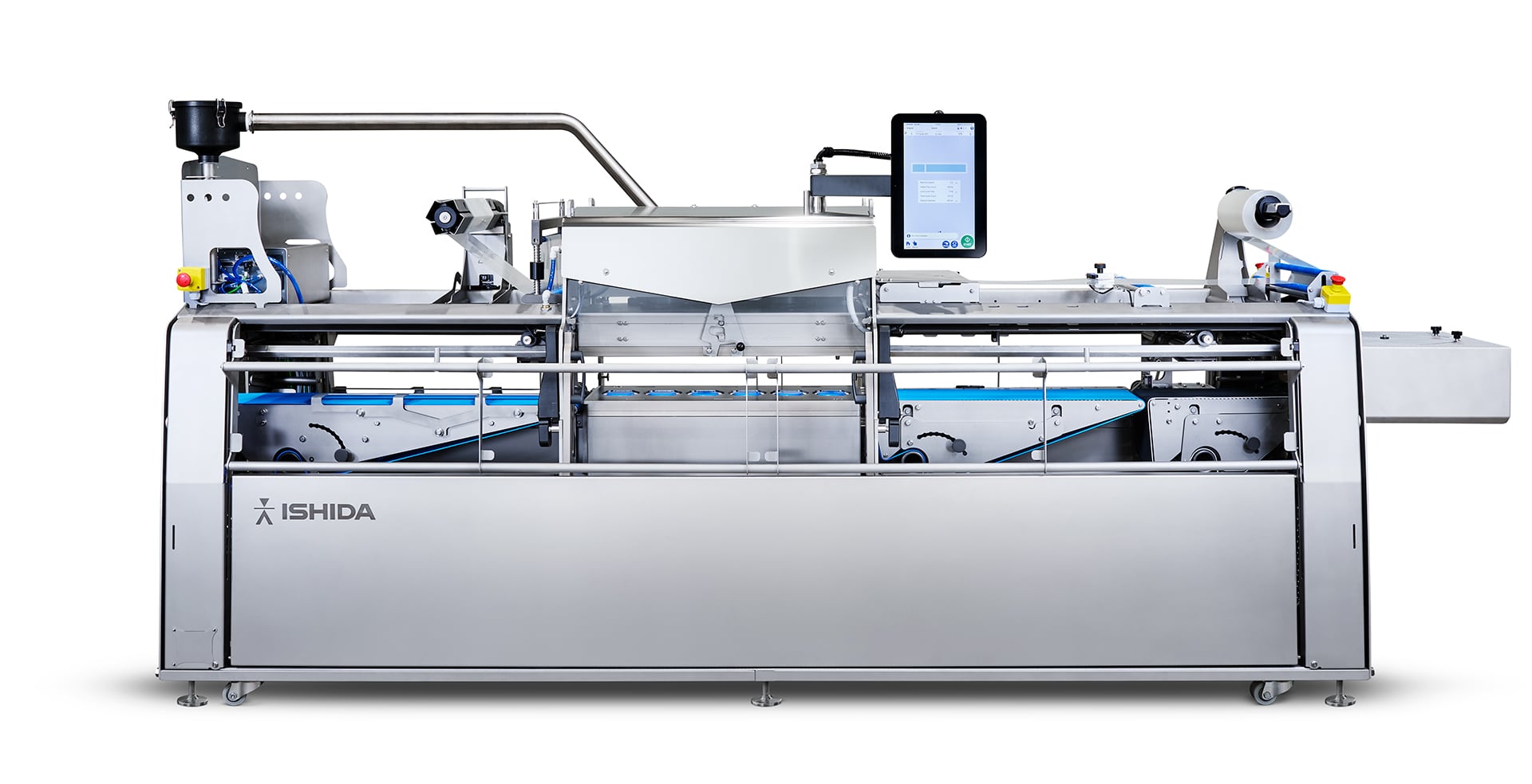

For instance, Ishida’s latest tray sealer, the QX-800, operates at speeds of up to 17 cycles per minute for MAP packs, ensuring high throughput. Its mechanical sealing system enhances sealing accuracy, while its patented tray transfer system significantly reduces the likelihood of spillage during transfer.

Meat processors should also consider future scenarios regarding pack formats. The QX-800 excels in this area, as it can easily handle multiple formats through its innovative tooling. Consequently, should retailers shift from MAP packs to skin packs or other sustainable alternatives, the QX-800 can adapt quickly, eliminating the need for additional investments in new machinery and floor space.

Unseen, Not Undetected

Additionally, a significant concern for MAP packs is the presence of microscopic leaks. While the naked eye can often detect whether a tray is sealed, microleaks can allow gases integral to the MAP process to escape, thereby compromising product integrity. More troubling is that these leaks can be so minuscule that they may pass conventional burst tests designed to identify weak points under high air pressure.

Although strides have been made to improve microleak detection, many existing methods remain rudimentary and prone to error. Techniques may range from a production manager squeezing the pack to feel for air escaping, to packaging bath tests that involve submerging packs in water to observe for gas bubbles signifying leaks.

While any form of testing is better than none, these methods only assess the integrity of a single pack at a specific moment. To mitigate financial and reputational risks associated with inadequate sealing across packaging cycles, stakeholders must adopt a broader, more comprehensive approach.

Slow Batch to Fast-Moving

Integrating leak detection for MAP applications inline presents a viable solution, significantly reducing the risk of costly stock returns and preserving relationships with retailers. Previously, leak detection relied on slow batch processes that often compromised product quality, leading to additional waste and revenue loss.

Ishida’s AirScan leak detection system exemplifies advanced technology in action, testing products rapidly without damaging rejected items. Capable of checking up to 160 packs per minute, it efficiently detects CO2 leaks from apertures as small as 0.5 mm, yielding reliable results for packs with carbon dioxide levels as low as 10%. Thus, meat processors can enhance throughput with minimal human intervention.

Despite the retailer-driven push for more sustainable packaging, meat processors must persist in exploring best practices through the seamless integration of tray sealing technology and inline leak detection. This proactive approach not only reduces MAP failure rates but also mitigates their financial and reputational ramifications.

By leveraging specialized expertise and advanced technologies, including Ishida’s AirScan and QX-800 tray sealer, businesses can ensure seal integrity, comply with evolving regulations, and ultimately enhance their operations alongside financial performance.